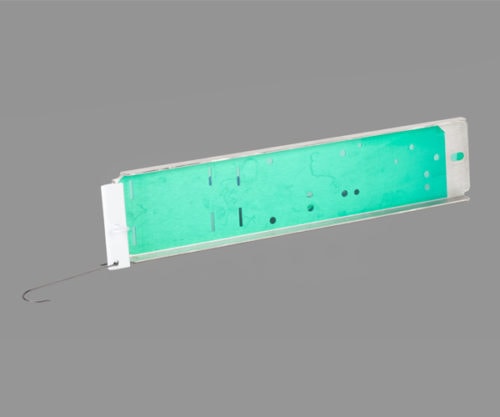

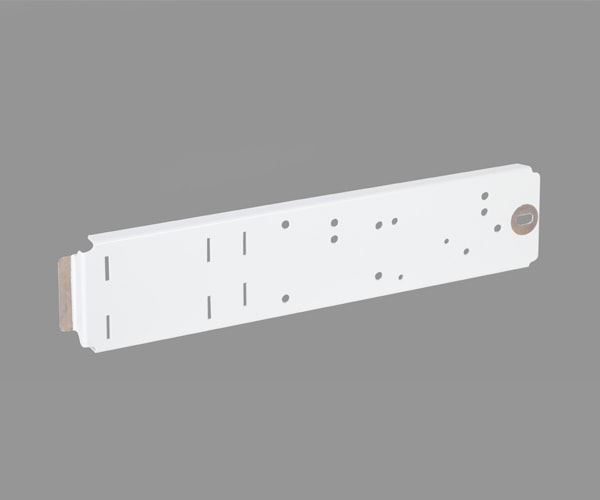

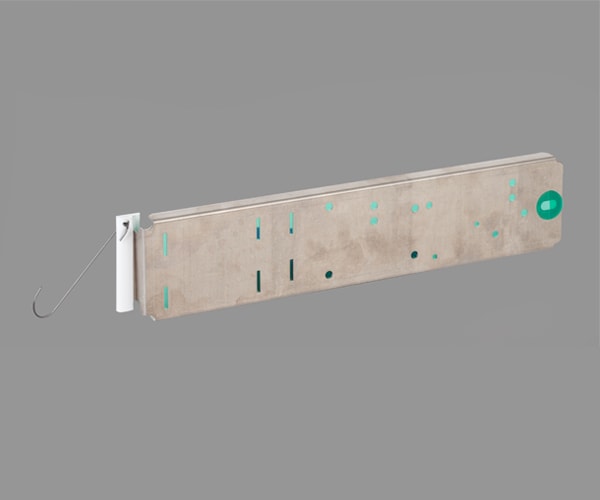

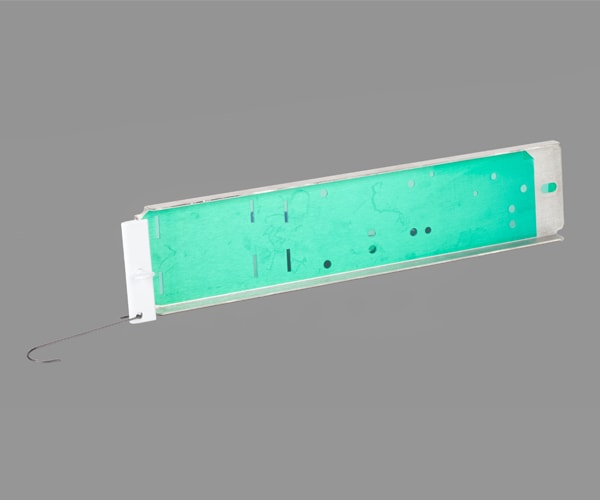

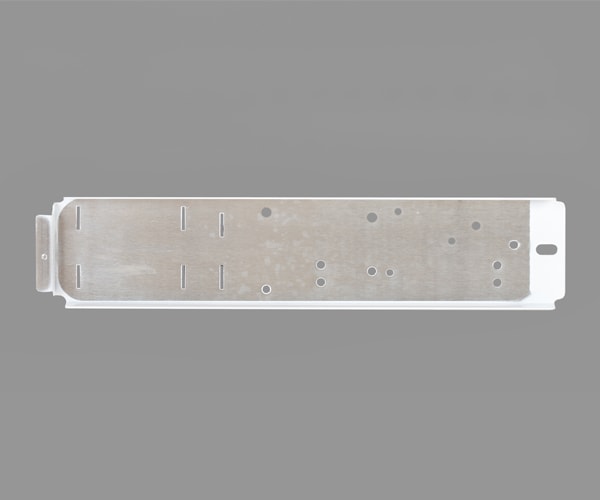

At Pyramid Fab and Finish, we fabricate and powder coat a great number of different types of parts, each with its own unique requirements. To produce the lighting bracket highlighted here, we started with .050″ thick aluminum sheet. Using a CNC controlled turret press along with a press brake equipped with a backgauge that allows precise positioning of the workpiece, we created the geometries and precisely punched the cutouts as specified in the customer drawings. We then cleanly masked off the non-coated features and applied a white powder finish.

When completed, the bracket measured 15.3″ in length x 3.3″ in width. Both in-process and final dimensional and visual inspection validated that we met the ±.005″ tolerance requirement. Our precision craftsmanship allowed for easy installation, and the durable finish was guaranteed not to crack or peel, even when exposed to direct heat.

Additional information about this project can be found in the table below. If you have a similar project, we would welcome the opportunity to provide you with a quote. contact us today.