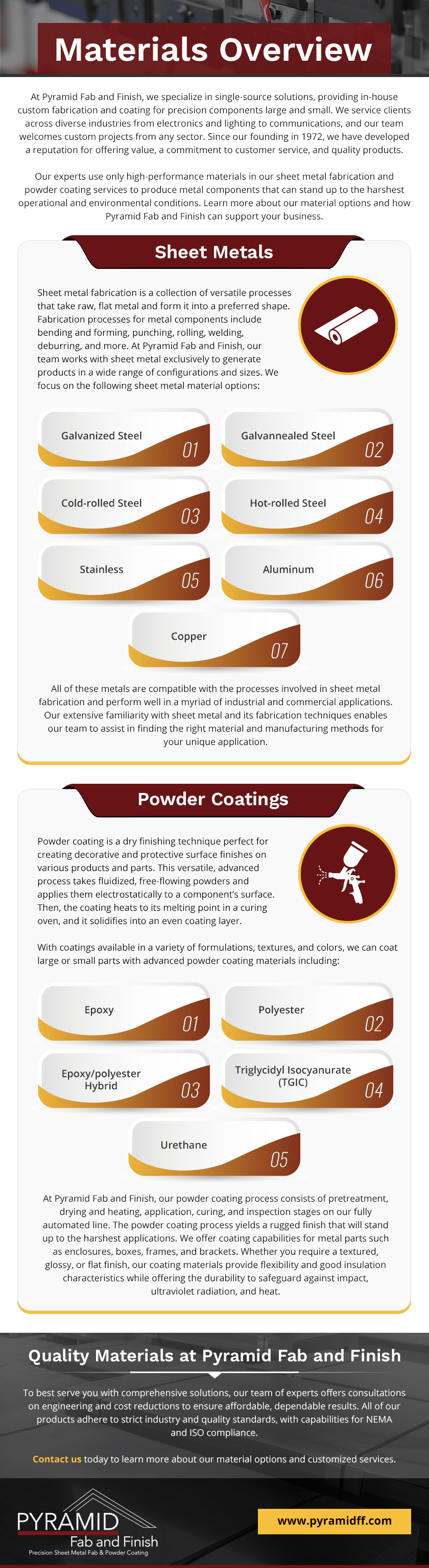

At Pyramid Fab and Finish, we specialize in single-source solutions, providing in-house custom fabrication and coating for precision components large and small. We service clients across diverse industries from electronics and lighting to communications, and our team welcomes custom projects from any sector. Since our founding in 1972, we have developed a reputation for offering value, a commitment to customer service, and quality products.

Our experts use only high-performance materials in our sheet metal fabrication and powder coating services to produce metal components that can stand up to the harshest operational and environmental conditions. Learn more about our material options and how Pyramid Fab and Finish can support your business.

Sheet Metals

Sheet metal fabrication is a collection of versatile processes that take raw, flat metal and form it into a preferred shape. Fabrication processes for metal components include bending and forming, punching, rolling, welding, deburring, and more. At Pyramid Fab and Finish, our team works with sheet metal exclusively to generate products in a wide range of configurations and sizes. We focus on the following sheet metal material options:

- Galvanized steel

- Galvannealed steel

- Cold-rolled steel

- Hot-rolled steel

- Stainless

- Aluminum

- Copper

All of these metals are compatible with the processes involved in sheet metal fabrication and perform well in a myriad of industrial and commercial applications. Our extensive familiarity with sheet metal and its fabrication techniques enables our team to assist in finding the right material and manufacturing methods for your unique application.

Powder Coatings

Powder coating is a dry finishing technique perfect for creating decorative and protective surface finishes on various products and parts. This versatile, advanced process takes fluidized, free-flowing powders and applies them electrostatically to a component’s surface. Then, the coating heats to its melting point in a curing oven, and it solidifies into an even coating layer.

With coatings available in a variety of formulations, textures, and colors, we can coat large or small parts with advanced powder coating materials including:

- Epoxy

- Polyester

- Epoxy/polyester hybrid

- Triglycidyl isocyanurate (TGIC)

- Urethane

At Pyramid Fab and Finish, our powder coating process consists of pretreatment, drying and heating, application, curing, and inspection stages on our fully automated line. The powder coating process yields a rugged finish that will stand up to the harshest applications. We offer coating capabilities for metal parts such as enclosures, boxes, frames, and brackets. Whether you require a textured, glossy, or flat finish, our coating materials provide flexibility and good insulation characteristics while offering the durability to safeguard against impact, ultraviolet radiation, and heat.

Quality Materials at Pyramid Fab and Finish

Pyramid Fab and Finish provides custom sheet metal and powder coating solutions for a broad spectrum of diverse applications. Our family-owned company serves industries such as power supply, medical equipment, industrial lighting, printing, and more. We utilize precision computer numerical control (CNC) technology in our turrets and brake presses to achieve tolerances of ±0.005 inches in materials like aluminum and steel, and our advanced conveyorized powder coating line allows us to offer superior coating and assembly services with no outsourcing necessary.

To best serve you with comprehensive solutions, our team of experts offers consultations on engineering and cost reductions to ensure affordable, dependable results. All of our products adhere to strict industry and quality standards, with capabilities for NEMA and ISO compliance.

Contact us today to learn more about our material options and customized services.