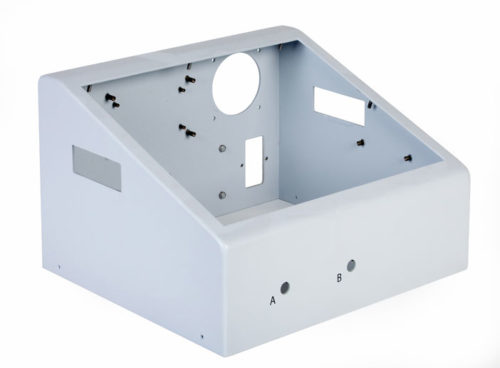

Since opening our doors in 1972, Pyramid Fab and Finish has developed a client base in a broad range of industries, and we are familiar with the standards and requirements unique to each. We manufactured the control housing shown here for a customer in the medical industry.

Since opening our doors in 1972, Pyramid Fab and Finish has developed a client base in a broad range of industries, and we are familiar with the standards and requirements unique to each. We manufactured the control housing shown here for a customer in the medical industry.

Constructed from .125″ thick aluminum, it features overall finished dimensions of 12.0″ in length, 14.0″ in width, and 9.0″ in height. Our CNC controlled press brakes and punch presses, combined with a conveyorized powder coating line and automatic hardware insertion equipment, allowed us to produce this job rapidly, economically, and within the customer specified five week timeline.

Notable features include counterbored holes in locations where the fastener was required to sit flush with the workpiece surface, silkscreening, and a easy-to-clean gray micro-texture powder. By maintaining focused attention on quality at each phase of the manufacturing cycle, we were able to uphold ±.005″ dimensional tolerances. Current production for this product is in the range of 50-250 units per order.

If you are interested in learning more about this project or any of our comprehensive set of fabrication services, contact us today.