Enclosures are box-like structures designed to protect electrical equipment from environmental factors, such as weather, corrosive solvents, electromagnetic interference, vibration, and liquid ingress. To ensure the proper protection of electrical components, it’s important to choose the right electrical enclosure for the intended application. At Pyramid Fab & Finish, we fabricate custom outdoor and indoor enclosures for many applications in the energy and battery storage industries.

Read on to learn more about custom enclosures, common types, and how Pyramid Fab & Finish can fabricate a custom electrical enclosure to protect your valuable equipment.

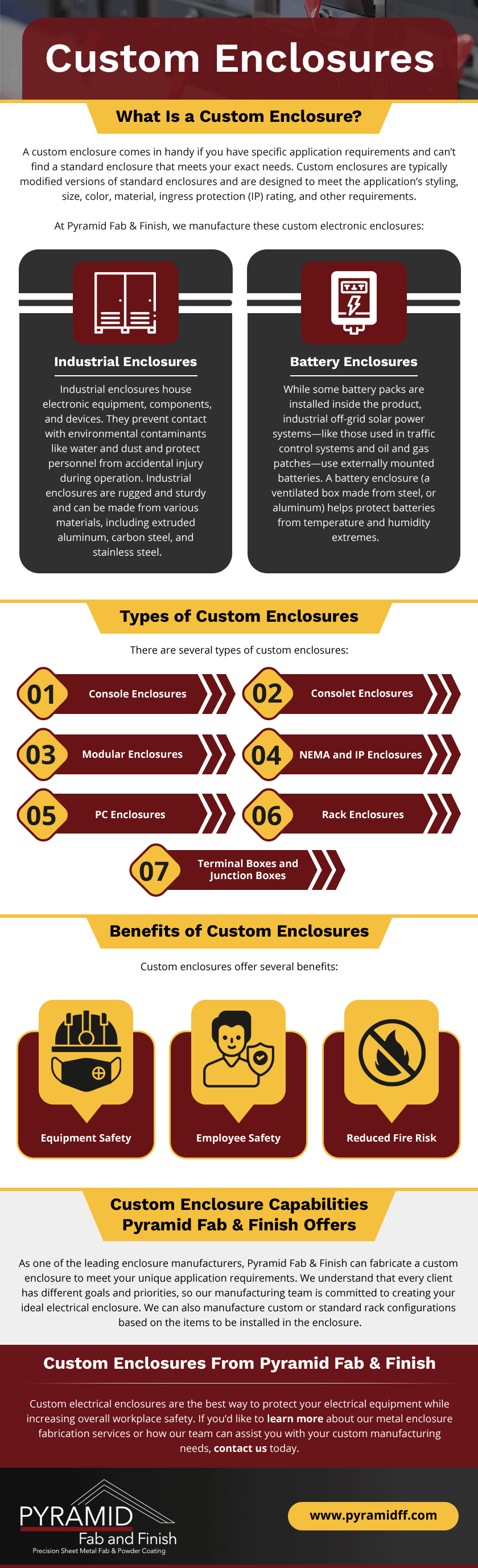

What Is a Custom Enclosure?

A custom enclosure comes in handy if you have specific application requirements and can’t find a standard enclosure that meets your exact needs. Custom enclosures are typically modified versions of standard enclosures and are designed to meet the application’s styling, size, color, material, ingress protection (IP) rating, and other requirements.

At Pyramid Fab & Finish, we manufacture these custom electronic enclosures:

- Industrial enclosures: Industrial enclosures house electronic equipment, components, and devices. They prevent contact with environmental contaminants like water and dust and protect personnel from accidental injury during operation. Industrial enclosures are rugged and sturdy and can be made from various materials, including extruded aluminum, diecast aluminum, carbon steel, and stainless steel.

- Battery enclosures: While some battery packs are installed inside the product, industrial off-grid solar power systems—like those used in traffic control systems and oil and gas patches—use externally mounted batteries. A battery enclosure (a ventilated box made from steel, fiberglass, or aluminum) helps protect batteries from temperature and humidity extremes.

Types of Custom Enclosures

There are several types of custom enclosures:

- Console enclosures: These are freestanding enclosures with a sloped front or top for mounting electronic control components.

- Consolet enclosures: Consolet enclosures are designed to house electronic or electric instruments and controls, such as pushbuttons. They feature a sloped front for mounting in either a 30° or 60° incline on either side.

- Modular enclosures: These enclosures come in standardized dimensions, allowing for easy rearrangement to create customized enclosures or larger cabinets.

- NEMA and IP enclosures: National Electrical Manufacturers Association (NEMA) protection ratings and ingress protection (IP) standards classify an enclosure’s protection level from foreign objects and moisture.

- PC enclosures: These enclosures are used to protect personal computers (PCs) in industrial settings.

- Rack enclosures: Rack enclosures commonly house standard 19-inch equipment or other rack-mounted devices, such as server modules or wall mounts.

- Terminal boxes and junction boxes: These rectangular enclosures protect sensitive electrical connections. You will commonly find them in engine and electrical rooms.

Benefits of Custom Enclosures

Custom enclosures offer several benefits:

- Equipment safety: Heat produced by electrical equipment can cause insulation damage, component failure, and even complete system failure. Using a custom electrical enclosure allows you to regulate the temperatures, effectively increasing your equipment’s lifespan. Custom electronic enclosures also feature locking mechanisms that protect your equipment from theft or tampering.

- Employee safety: Unenclosed electrical equipment is a safety hazard, especially when employees work in close proximity. The heat produced by your electrical equipment can accumulate to uncomfortable levels and cause dehydration, cramps, headaches, heat stroke, rashes, and even death. Employees can also get burned if they touch an unenclosed electrical component. Electrical enclosures contain the thermal effects of electrical operation, improving employee safety and comfort.

- Reduced fire risk: Sometimes electrical panels malfunction or give off sparks, resulting in an electrical fire that can spread quickly. A custom electrical enclosure protects internal components and external surroundings from fire risk.

Custom Enclosure Capabilities Pyramid Fab & Finish Offers

As one of the leading enclosure manufacturers, Pyramid Fab & Finish can fabricate a custom enclosure to meet your unique application requirements. We understand that every client has different goals and priorities, so our manufacturing team is committed to creating your ideal electrical enclosure. We can also manufacture custom or standard rack configurations based on the items to be installed in the enclosure.

Custom Enclosures From Pyramid Fab & Finish

Custom electrical enclosures are the best way to protect your electrical equipment while increasing overall workplace safety. If you’d like to learn more about our metal enclosure fabrication services or how our team can assist you with your custom manufacturing needs, contact us today.