Interesting Facts You Didn’t Know About Custom Sheet Metal Fabrication

Leave a Comment Did you know that custom sheet metal fabrication is a process that can be used to create anything from large electronic enclosures to medical control boxes and anything in between? It’s a versatile technology with many applications, and there are some interesting facts about it that you may not know. This blog post will share some of the most interesting things about custom sheet metal fabrication, its uses, and more!

Did you know that custom sheet metal fabrication is a process that can be used to create anything from large electronic enclosures to medical control boxes and anything in between? It’s a versatile technology with many applications, and there are some interesting facts about it that you may not know. This blog post will share some of the most interesting things about custom sheet metal fabrication, its uses, and more!

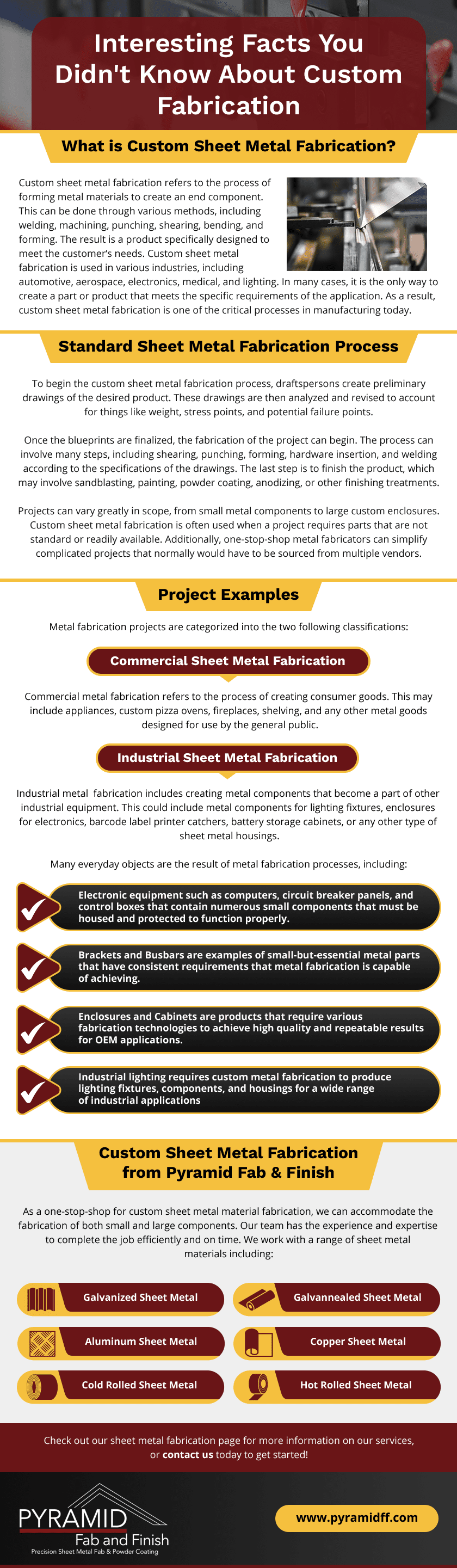

What is Custom Sheet Metal Fabrication?

Custom sheet metal fabrication refers to the process of forming metal materials to create an end component. This can be done through various methods, including welding, machining, punching, shearing, bending, and forming. The result is a product specifically designed to meet the customer’s needs. Custom sheet metal fabrication is used in various industries, including automotive, aerospace, electronics, medical, and lighting. In many cases, it is the only way to create a part or product that meets the specific requirements of the application. As a result, custom sheet metal fabrication is one of the critical processes in manufacturing today.

Standard Sheet Metal Fabrication Process

To begin the custom sheet metal fabrication process, draftspersons create preliminary drawings of the desired product. These drawings are then analyzed and revised to account for things like weight, stress points, and potential failure points.

Once the blueprints are finalized, the fabrication of the project can begin. The process can involve many steps, including shearing, punching, forming, hardware insertion, and welding according to the specifications of the drawings. The last step is to finish the product, which may involve sandblasting, painting, powder coating, anodizing, or other finishing treatments.

Projects can vary greatly in scope, from small metal components to large custom enclosures. Custom sheet metal fabrication is often used when a project requires parts that are not standard or readily available. Additionally, one-stop-shop metal fabricators can simplify complicated projects that normally would have to be sourced from multiple vendors.

Project Examples

Metal fabrication projects are categorized into the two following classifications:

Commercial Sheet Metal Fabrication

Commercial metal fabrication refers to the process of creating consumer goods. This may include appliances, custom pizza ovens, fireplaces, shelving, and any other metal goods designed for use by the general public.

Industrial Sheet Metal Fabrication

Industrial metal fabrication includes creating metal components that become a part of other industrial equipment. This could include metal components for lighting fixtures, enclosures for electronics, barcode label printer catchers, battery storage cabinets, or any other type of sheet metal housings.

Many everyday objects are the result of metal fabrication processes, including:

- Electronic equipment such as computers, circuit breaker panels, and control boxes that contain numerous small components that must be housed and protected to function properly.

- Brackets and Busbars are examples of small-but-essential metal parts that have consistent requirements that metal fabrication is capable of achieving.

- Enclosures and Cabinets are products that require various fabrication technologies to achieve high quality and repeatable results for OEM applications.

- Industrial lighting requires custom metal fabrication to produce lighting fixtures, components, and housings for a wide range of industrial applications

Custom Sheet Metal Fabrication from Pyramid Fab & Finish

As a one-stop-shop for custom sheet metal material fabrication, we can accommodate the fabrication of both small and large components. Our team has the experience and expertise to complete the job efficiently and on time. We work with a range of sheet metal materials including:

- Galvanized sheet metal

- Galvannealed sheet metal

- Aluminum sheet metal

- Copper sheet metal

- Cold rolled sheet metal

Check out our sheet metal fabrication page for more information on our services, or contact us today to get started!

Benefits of Working With A Full-Service Sheet Metal Fabrication Company

Leave a Comment Oftentimes manufacturers will look for a custom metal fabricator based on capabilities, production, or process. In many cases, they end up with multiple vendors to accomplish the necessary steps required to create the desired end component to their specifications. Unfortunately, this can lead to some challenges in quality, cost control, and communication that could negatively impact the efficiency of the production process.

Oftentimes manufacturers will look for a custom metal fabricator based on capabilities, production, or process. In many cases, they end up with multiple vendors to accomplish the necessary steps required to create the desired end component to their specifications. Unfortunately, this can lead to some challenges in quality, cost control, and communication that could negatively impact the efficiency of the production process.

Instead of sourcing multiple vendors, manufacturers should look for a full-service sheet metal fabrication company to achieve more control over cost and quality and ensure the delivery of high-quality products that exceed expectations. Here are some things you should know when looking for a full-service partner.

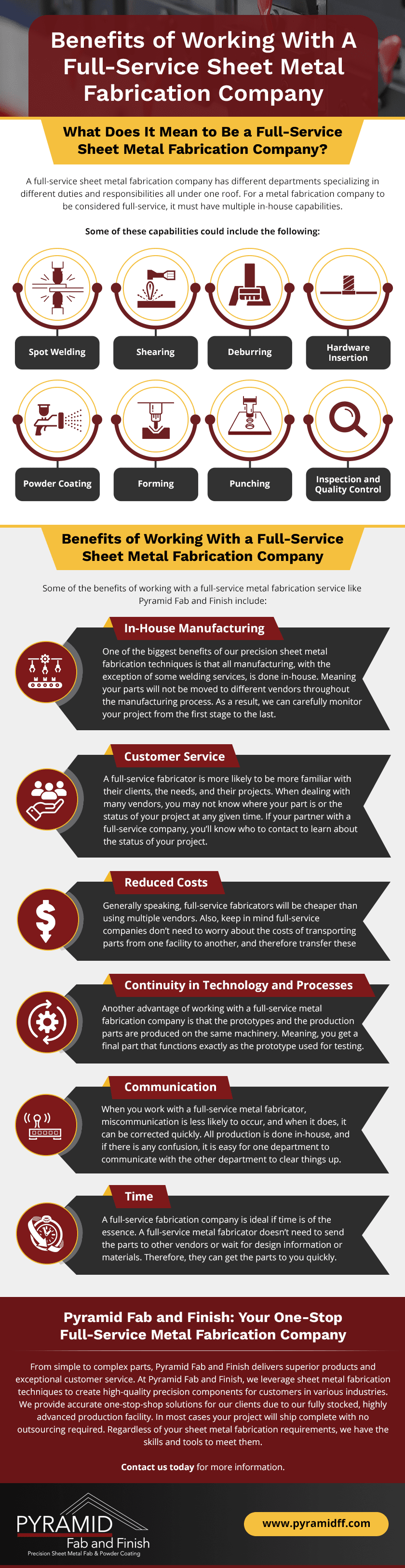

What Does It Mean to Be a Full-Service Sheet Metal Fabrication Company?

A full-service sheet metal fabrication company has different departments specializing in different duties and responsibilities all under one roof. For a metal fabrication scompany to be considered full-service, it must have multiple in-house capabilities.

Some of these capabilities could include the following:

- Cutting

- Shearing

- Deburring

- Hardware insertion

- Spot Welding

- Machining

- Punching

- Inspection and Quality Control

- Powder Coating

- Forming

Benefits of Working With a Full-Service Sheet Metal Fabrication Company

Some of the benefits of working with a full-service metal fabrication service like Pyramid Fab and Finish include:

- In-house manufacturing: One of the biggest benefits of our precision sheet metal fabrication techniques is that all manufacturing, with the exception of some welding services, is done in-house. Meaning your parts will not be moved to different vendors throughout the manufacturing process. As a result, we can carefully monitor your project from the first stage to the last.

- Customer service: A full-service fabricator is more likely to be more familiar with their clients, the needs, and their projects. When dealing with many vendors, you may not know where your part is or the status of your project at any given time. If your partner with a full-service company, you’ll know who to contact to learn about the status of your project.

- Reduced costs: Generally speaking, full-service fabricators will be cheaper than using multiple vendors. Also, keep in mind full-service companies don’t need to worry about the costs of transporting parts from one facility to another, and therefore transfer these cost savings to the client.

- Continuity in technology and processes: Another advantage of working with a full-service metal fabrication company is that the prototypes and the production parts are produced on the same machinery. Meaning, you get a final part that functions exactly as the prototype used for testing.

- Communication: When you work with a full-service metal fabricator, miscommunication is less likely to occur, and when it does, it can be corrected quickly. All production is done in-house, and if there is any confusion, it is easy for one department to communicate with the other department to clear things up.

- Time: A full-service fabrication company is ideal if time is of the essence. A full-service metal fabricator doesn’t need to send the parts to other vendors or wait for design information or materials. Therefore, they can get the parts to you quickly.

Pyramid Fab and Finish: Your One-Stop Full-Service Metal Fabrication Company

From simple to complex parts, Pyramid Fab and Finish delivers superior products and exceptional customer service. At Pyramid Fab and Finish, we leverage sheet metal fabrication techniques to create high-quality precision components for customers in various industries. We provide accurate one-stop-shop solutions for our clients owing to a fully stocked, highly advanced production facility. In most cases your project will ship complete with no outsourcing required. Regardless of your sheet metal fabrication requirements, we have the skills and tools to meet them.

Contact us today for more information.

Contact Us