Did you know that custom sheet metal fabrication is a process that can be used to create anything from large electronic enclosures to medical control boxes and anything in between? It’s a versatile technology with many applications, and there are some interesting facts about it that you may not know. This blog post will share some of the most interesting things about custom sheet metal fabrication, its uses, and more!

Did you know that custom sheet metal fabrication is a process that can be used to create anything from large electronic enclosures to medical control boxes and anything in between? It’s a versatile technology with many applications, and there are some interesting facts about it that you may not know. This blog post will share some of the most interesting things about custom sheet metal fabrication, its uses, and more!

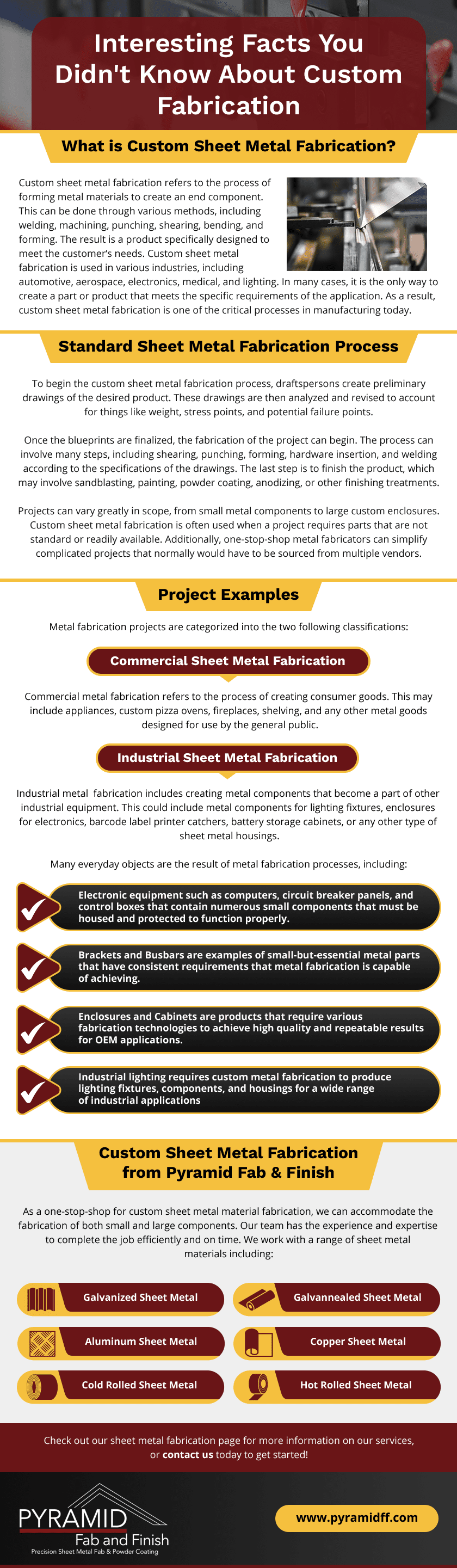

What is Custom Sheet Metal Fabrication?

Custom sheet metal fabrication refers to the process of forming metal materials to create an end component. This can be done through various methods, including welding, machining, punching, shearing, bending, and forming. The result is a product specifically designed to meet the customer’s needs. Custom sheet metal fabrication is used in various industries, including automotive, aerospace, electronics, medical, and lighting. In many cases, it is the only way to create a part or product that meets the specific requirements of the application. As a result, custom sheet metal fabrication is one of the critical processes in manufacturing today.

Standard Sheet Metal Fabrication Process

To begin the custom sheet metal fabrication process, draftspersons create preliminary drawings of the desired product. These drawings are then analyzed and revised to account for things like weight, stress points, and potential failure points.

Once the blueprints are finalized, the fabrication of the project can begin. The process can involve many steps, including shearing, punching, forming, hardware insertion, and welding according to the specifications of the drawings. The last step is to finish the product, which may involve sandblasting, painting, powder coating, anodizing, or other finishing treatments.

Projects can vary greatly in scope, from small metal components to large custom enclosures. Custom sheet metal fabrication is often used when a project requires parts that are not standard or readily available. Additionally, one-stop-shop metal fabricators can simplify complicated projects that normally would have to be sourced from multiple vendors.

Project Examples

Metal fabrication projects are categorized into the two following classifications:

Commercial Sheet Metal Fabrication

Commercial metal fabrication refers to the process of creating consumer goods. This may include appliances, custom pizza ovens, fireplaces, shelving, and any other metal goods designed for use by the general public.

Industrial Sheet Metal Fabrication

Industrial metal fabrication includes creating metal components that become a part of other industrial equipment. This could include metal components for lighting fixtures, enclosures for electronics, barcode label printer catchers, battery storage cabinets, or any other type of sheet metal housings.

Many everyday objects are the result of metal fabrication processes, including:

- Electronic equipment such as computers, circuit breaker panels, and control boxes that contain numerous small components that must be housed and protected to function properly.

- Brackets and Busbars are examples of small-but-essential metal parts that have consistent requirements that metal fabrication is capable of achieving.

- Enclosures and Cabinets are products that require various fabrication technologies to achieve high quality and repeatable results for OEM applications.

- Industrial lighting requires custom metal fabrication to produce lighting fixtures, components, and housings for a wide range of industrial applications

Custom Sheet Metal Fabrication from Pyramid Fab & Finish

As a one-stop-shop for custom sheet metal material fabrication, we can accommodate the fabrication of both small and large components. Our team has the experience and expertise to complete the job efficiently and on time. We work with a range of sheet metal materials including:

- Galvanized sheet metal

- Galvannealed sheet metal

- Aluminum sheet metal

- Copper sheet metal

- Cold rolled sheet metal

Check out our sheet metal fabrication page for more information on our services, or contact us today to get started!